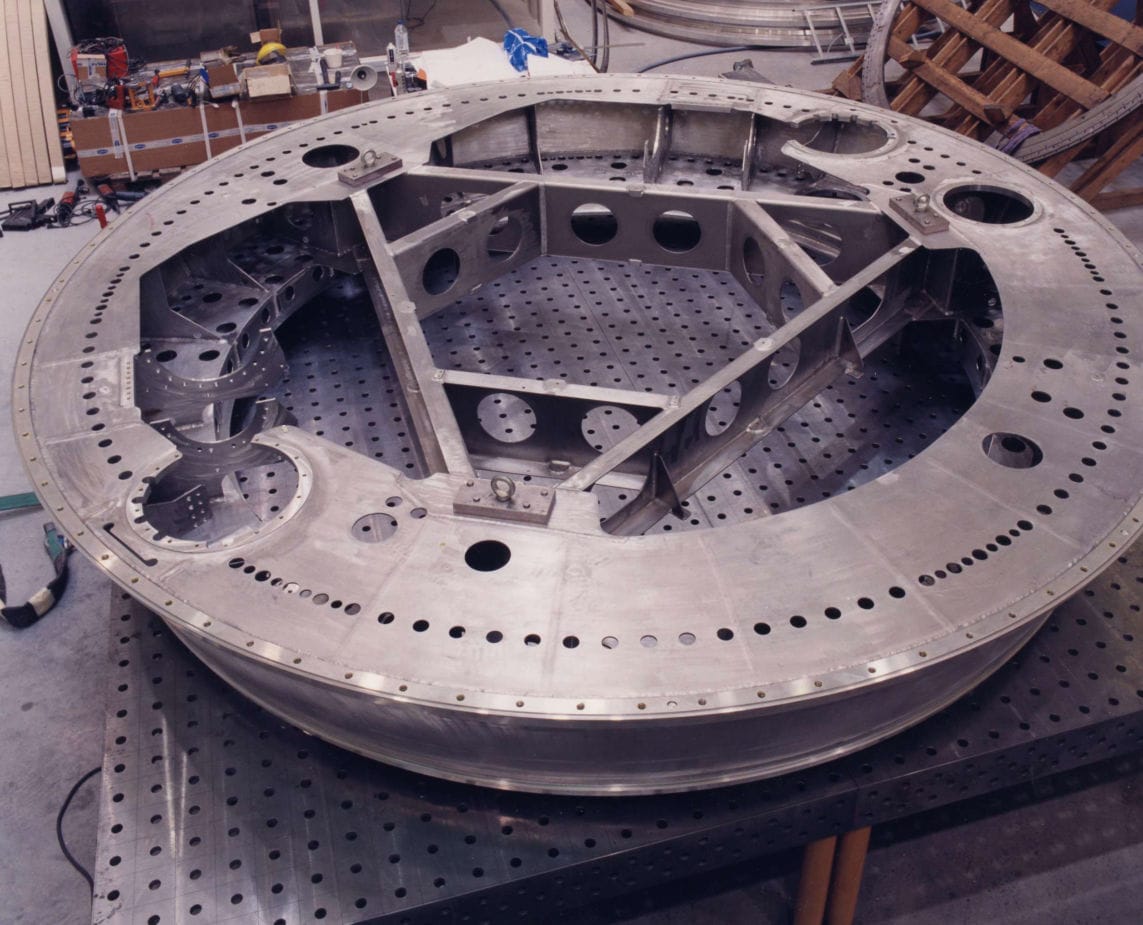

High-precision 4m conical support and floors for marine radar antenna

The cone is a complex aluminium (5082 H112) welded structure constituting the connection between the complete antenna system (dimension of antenna = 8 x 4 m) and the deck of a naval ship. Because of the high environmental requirements (wind, salt spray, high humidity, nuclear blast), the cone was specified by our customer on the basis of high safety levels. The manufacturing of this part called for working with low tolerances (especially for the quality of the welding).

This part has a conical shape with a base external diameter of D = 4000 mm , with an upper external diameter of D = 3600 mm and a height of H = 590 mm. The external skin of the cone is composed of an upper and a lower forged ring welded on a conical skin of 8 mm. These welds are fully X-ray controlled. The cone also includes two internal horizontal plates and many radial beams welded on the external skin.

The lower ring is the interface face and the upper ring supports a bearing. These faces are machined with a flatness of 0.2 mm and with a parallelism of 0.5 mm. The horizontal plates have some machined flanges supporting motors and accessories (pumps,…). These flanges are machined with a parallelism of 0.2 mm compared to the upper face.

Amos was responsible for the complete manufacturing process of this part including work preparation, manufacturing, drawings, welding , annealing and machining.

The floor is a lightweight aluminium structure use to support the electronic cabinets of an antenna system ( dimension of antenna = 8 x 4 m) placed on a naval ship. The structure must be as light as possible but must have a good stiffness. The floor is composed of a central aluminium sandwich structure and of external ring assembled together with plates by gluing and riveting.

Amos was responsible for the manufacturing of the complete floor ( except sandwich part) including work preparation, manufacturing drawings, gluing and riveting, turning and drilling.

info@amos.be

info@amos.be

+32 4 361 40 40

+32 4 361 40 40

see all

Projects

see all

Projects