Diamond turning techniques

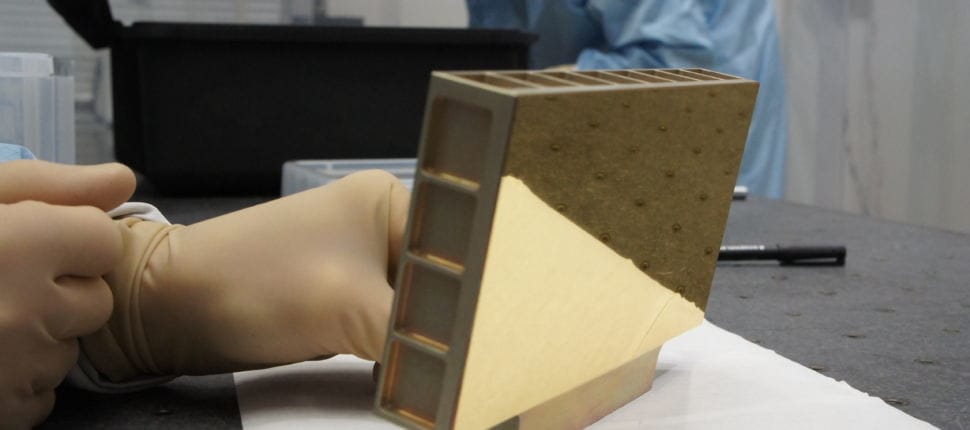

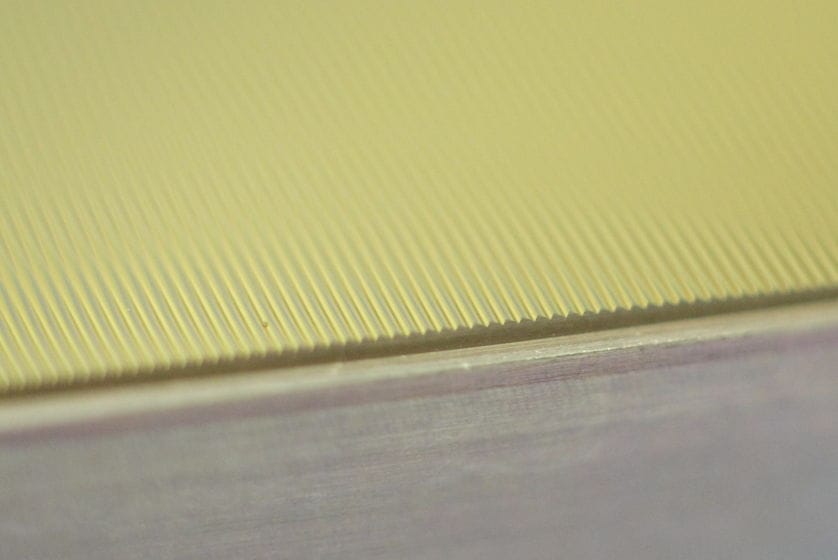

AMOS polishes the substrate then engraves the gratings using diamond turning techniques. This also enables a wide range of gratings.

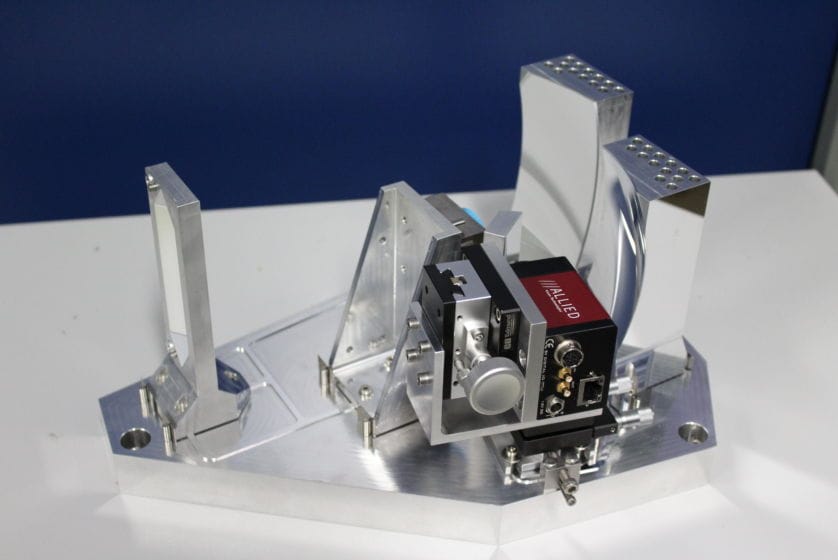

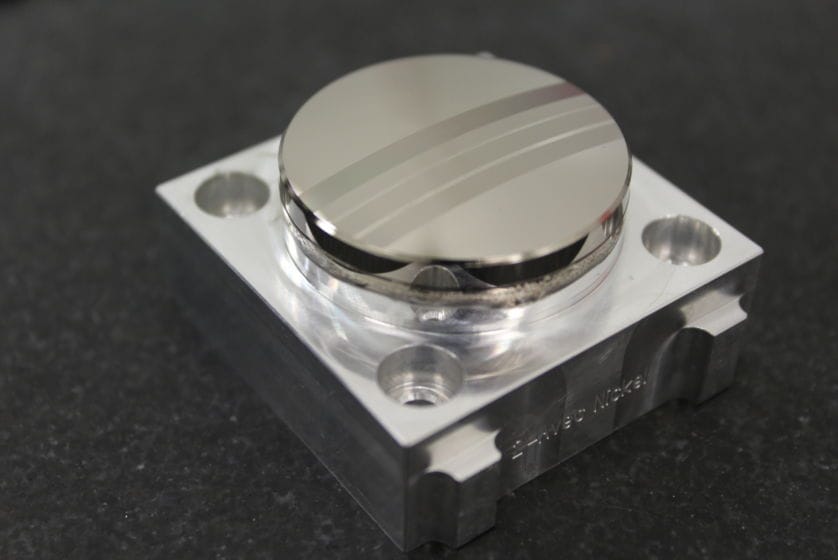

Diamond turning technique allows to manufacture small optical pieces for infrared applications and also, with post-polishing, for visible or ultraviolet. We produce concave and convex mirrors up to 500 mm diameter with extreme asphericities, also off-axis devices and freeform surfaces.

info@amos.be

info@amos.be

+32 4 361 40 40

+32 4 361 40 40