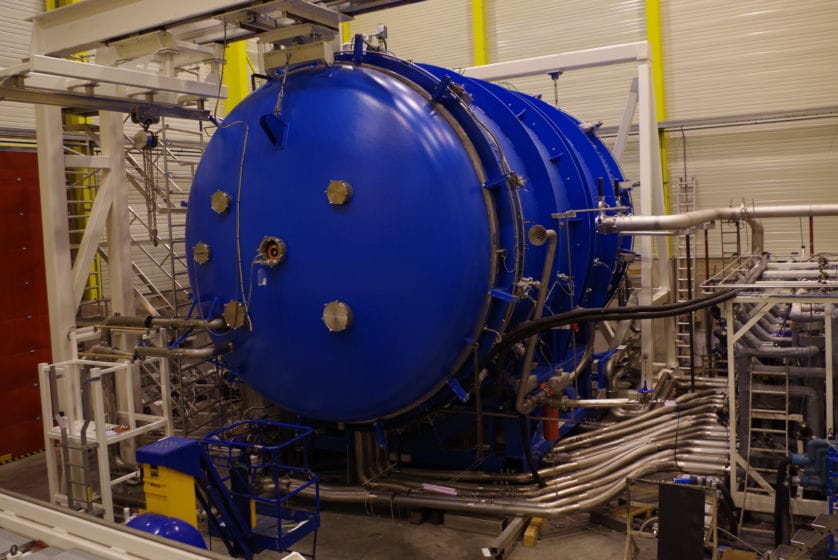

Vacuum chambers, space simulators, thermal-vacuum chambers

Space simulators are used to test space hardware with the pressure and temperature encountered in space.

Vacuum chambers are also used for scientific applications (particule accelerators for example) or industrial applications.

Chamber sizes range from 50 cm up to 13m long and 9m in diameter.

Temperatures can be as low as 1K using liquid Helium, or rise up to 150°C.

The chambers can also be equipped with solar simulators, optical benches or mechanical fixtures.

info@amos.be

info@amos.be

+32 4 361 40 40

+32 4 361 40 40